Sand Maker

Processing capacity: 12-360t/h

Processible materials: Coal, minerals, limestone, granite, sand gravel, sandstone, construction waste, concrete, iron ore, quartz, artificial sand, brick and tile, etc.

VSI sand maker, also known as VSI crusher, is high-performance sand making equipment with international advanced technology. VSI crusher is good primary crusher and secondary crusher with excellent performance, so it’s one of the most popular sand making machines in many countries. VSI crusher can continuously work 720 hours without stopping, is currently the latest mainstream equipment in sand making industries.

Advantages of Sand Maker

1. Larger crushing ratio: up to 40 per cent, and the VSI sand maker can instead of primary crusher and secondary crusher

2. Lower input, higher output: equal scale, the investment cost of VSI Crusher is lower 20%-35% than traditional sand making machines, while the productivity is higher 8%-15% than conventional sand making equipment

3. Lower maintenance costs: all wearing parts of VSI crushers are made of special hard wear-resistant materials with long service life to reduce maintenance costs. Long-term operation and maintenance cost is lower 35%-50% than comparable traditional sand making machines.

Applications of VSI sand maker

1. To make manufactured sand by using river pebbles, rocks (limestone, granite, basalt, diabase, andesite), ore tailings, etc.;

2. To produce construction aggregate, road pavement materials, bedding material, asphalt concrete and concrete aggregates;

3. To make machine-made sand and stone shaping in water conservancy and hydropower, roads, bridges, runways, municipal engineering, high-rise buildings, etc.;

4. Secondary crushing in the areas of building materials, metallurgy, chemicals, mining, refractory, cement, abrasive material, etc.

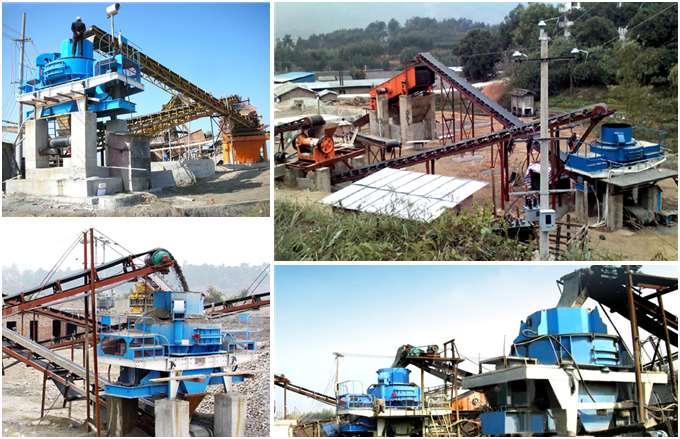

Sand making plant

A full sand making production line mainly includes feeder, crusher, VSI sand maker, vibrating screen, sand washing machine, and the sand maker is the core equipment. Our company designed sand making plant with international advanced standard after experience for decades years.

Artificial sand has become the mainstream in the market. Fote has more than 30 years experience in designing sand making plant, and has designed thousands of river sand and gravel sand production lines, granite sand production lines, etc. We welcome your inquiry, and design the most satisfactory sand making plant for you!

Technical Data

| Model | FTMVSI-7611 | FTMVSI-8518 | FTMVSI-9526 | FTMVSI-1140 | FTMVSI-1145 | FTMVSI-1150 | |

| Capacity (t/h) |

Feed both at center and sides |

80-180 | 140-260 | 200-380 | 300-520 | 350-610 | 360-650 |

| Feed at center |

40-90 | 70-130 | 100-190 | 160-260 | 180-355 | 190-365 | |

| Max.feeding size(mm) |

Soft material |

35 | 40 | 45 | 50 | 50 | 50 |

| Hard material |

30 | 35 | 40 | 40 | 45 | 45 | |

| Rotation speed (r/min) |

1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1150-1300 | 1150-1300 | |

| Double Motor power(kw) |

4P 110 | 4P 180 | 4P 264 | 4P 400 | 4P 440 | 4P 500 | |

| Overall dimension (L×W×H)(mm) |

3700×2150×2100 | 4140×2280×2425 | 4560×2447×2778 | 5100×2700×3300 | 5500×2700×3300 | 5500×2700×3300 | |

| Power supply | 380V 50HZ | ||||||

| Lubrication station |

Double motor power of oil pump |

2×0.31Kw | |||||

| Safety assuance |

The oil pump assure enough oil supply and automatic switch off with no oil pressure,air cooling or water cooling,motor heating start up in winter |

||||||

| Overall dimension (L×W×H) (mm) |

820×520×1270 | ||||||

| Power of oil tank heater |

2KW | ||||||

Navigation

Navigation